Custom Inspection Capabilities

Custom Solutions

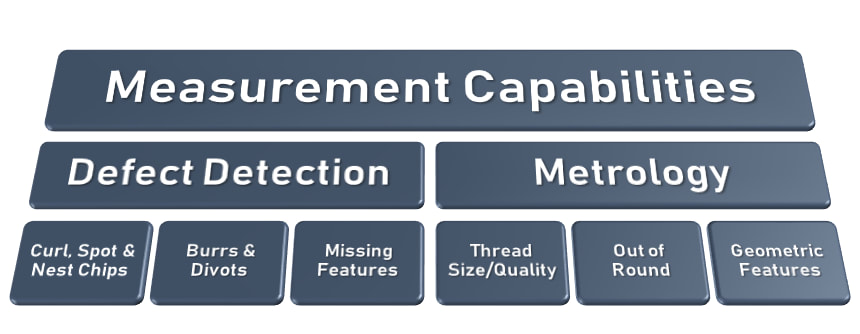

The team at Six Sigma Concepts has extensive experience developing inspection systems for unique problems. Whether a high inspection rate is required or a difficult feature requires inspection, we find solutions. We suggest the optimal reliable device that we can build to meet your criteria. We have developed metrology based sorters inspecting for chips, burrs, surface quality, thread integrity, shape deformation, feature presence, and more.

Examples of Custom Systems

Large Part High Resolution Inspection

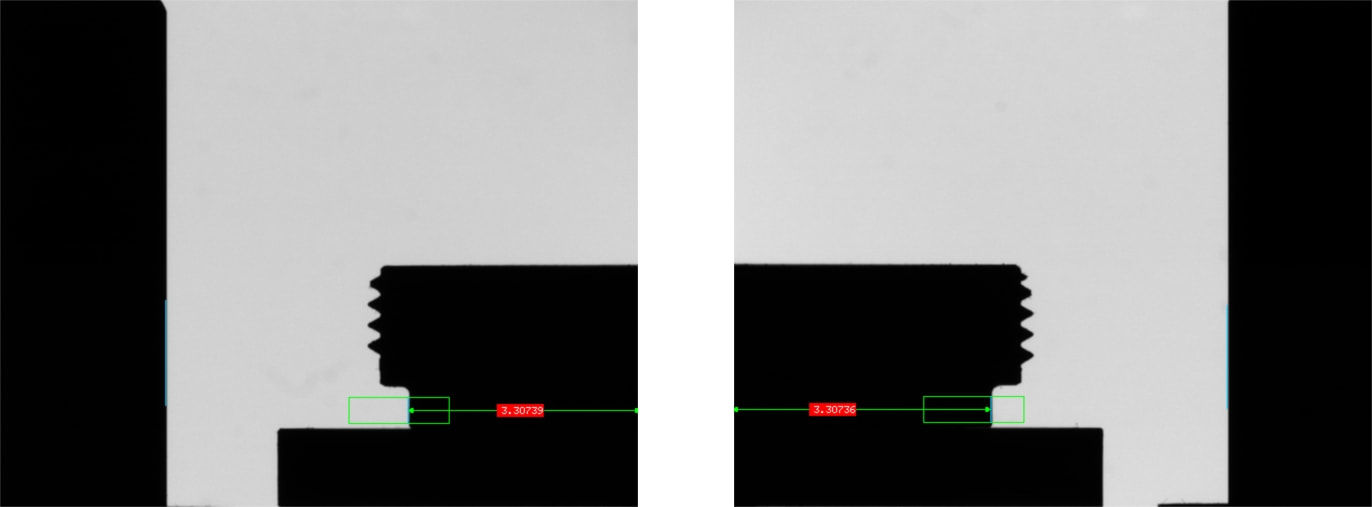

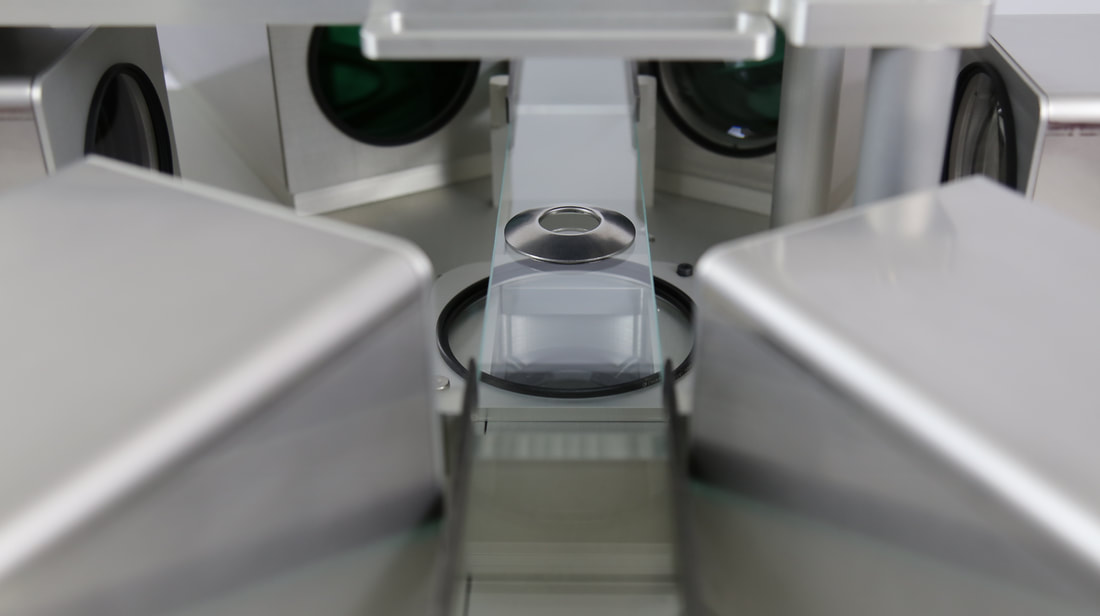

Problem: Measure diameters, threads, and geometric features of a large turned part with a high resolution.

Challenges: The parts to be inspected are too large to resolve to features with the necessary resolution with conventional vision inspection. Only measuring one side of the part will not be able to provide full part information. Solution: Aligning two separate imaging systems allows for high resolution of each side of the part, while being able to determine cross sectional diameter information. This device allows for the measurement of the threads, diameters, heights, radii, and shape warping. This measurement technique allows for parts of any diameter to be measured with a tolerance of 0.0001". |

Rapid Pin SortingProblem: Find coil pins with interior obstructions.

Challenges: Obstructions of various size need to be detected anywhere within the coil pin. Conventional imaging systems do not have the depth of focus to to resolve small obstructions across the length of the pin. Cross sectional imaging down the length of the pin would takes too long and has diffraction issues. Solution: A near collimated laser, used as the illumination source, allows for the detection of 0.010" obstructions anywhere along a 3" length. The imaging system can then use single shot measurements for sorting, allowing for a fast sorting process. |

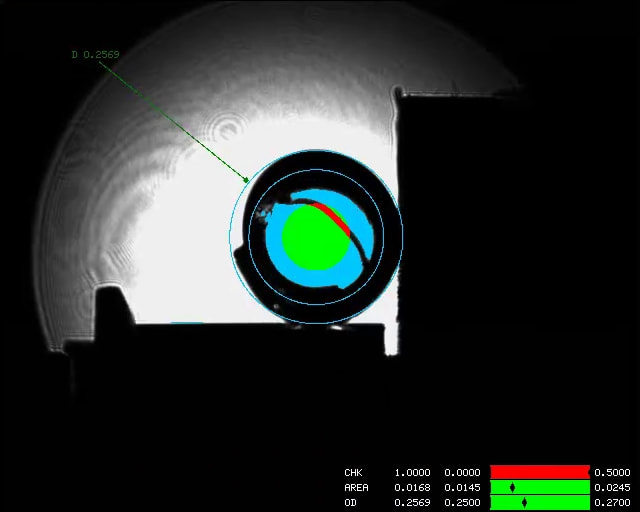

Replicating a CMM Spherical RadiusProblem: High throughput needed to match a CMM profile measurement of spherical washers.

Challenges: A single side profile image, such as from the Eclipse can not reliably catch warped out of spec parts. The 360° variant slows inspection and is not well suited for washers. Solution: Six Sigma has proved that it could reliably match the CMM performance inspecting the profile in three directions. A top camera was added to check on the OD & ID profile. The system is capable of sorting 4 washers per second. |

Tailored Systems

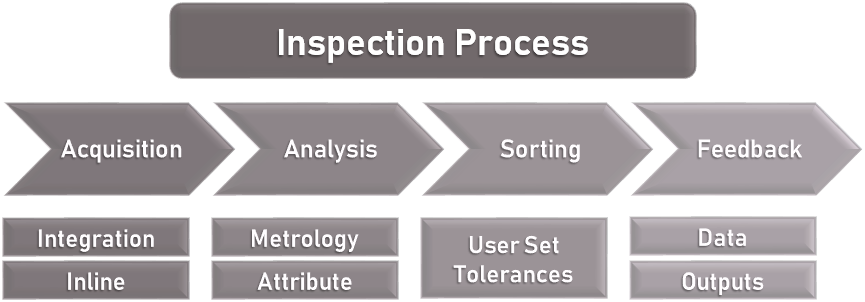

At Six Sigma Concepts we strive to provide a system with the capabilities most suited to the customer's requirements. We provide automation, integration, and feedback for customers needing rapid post-process response. We develop software tools customized to inspect each particular feature required and give the user the ability to define the tolerance goals and pass/fail criteria. We do not look to upsell unnecessary features, if we feel that a particular feature may be useful, but not necessary to fulfill the customer's requirements, we will make the feature optional for the customer.

If you have an inspection task requiring a custom solution, you can send us your information or contact us directly.

We look forward to hearing from you.