Precision Inspection and Sorting Systems

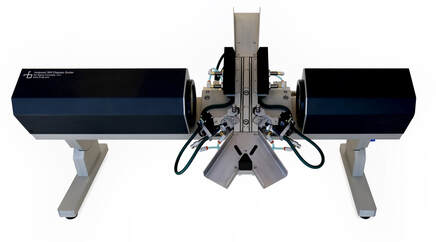

Eclipse Track Sorter

Customizable Sorting Solution

|

The Eclipse: Track Sorter uses a pneumatically controlled escapement to release parts down a track one at a time for inspection and sorting. The base unit analyzes a single snapshot of the part's profile as the part passes down the track. Two variants of the system allow for complete exterior profile and/or ID/OD inspection. The Eclipse platform is a great sorting solution for moderately sized, 1" - 2" OD, turned parts and tube cutoffs. Providing precise measurements of features such as:

|

For more details please visit the Eclipse page. Please contact us with any questions that you may have.

Orion Platen Sorters

Rapid Inspection & Sorting

|

The Orion Platen Sorter and Orion Mini Small Part Sorter are turnkey optical inspection and sorting machines with rapid part measurement and defect detection. Both utilize a tilted rotating glass platen with a metal ridge for part transport. Both systems can analyze and sort up to 10 parts per second with dimensional precision within 0.00005". These systems are ideal for sorting small turned parts, pins, and tube cutoff up to 0.625" in length and can sort small rings and washers.

The Orion194 inspection and sorting system uses a level glass platen to transport standing parts past an inspection point and onto sorting positions. Parts travel past an inspection point where their side profile and optionally their top profile are imaged and evaluated. They then travel onto sorting positions where they are ejected from the system based on their dimensions. The Orion197 also uses a tilted glass platen for part transport, but instead of traveling along the rim, parts travel across a linear rail. This motion induces a rotation in the part. The Orion197 can take multiple images of each part as it transits, ensuring that the entire outer profile is inspected. For more details please visit the Orion page. Please contact us with any questions that you may have. |