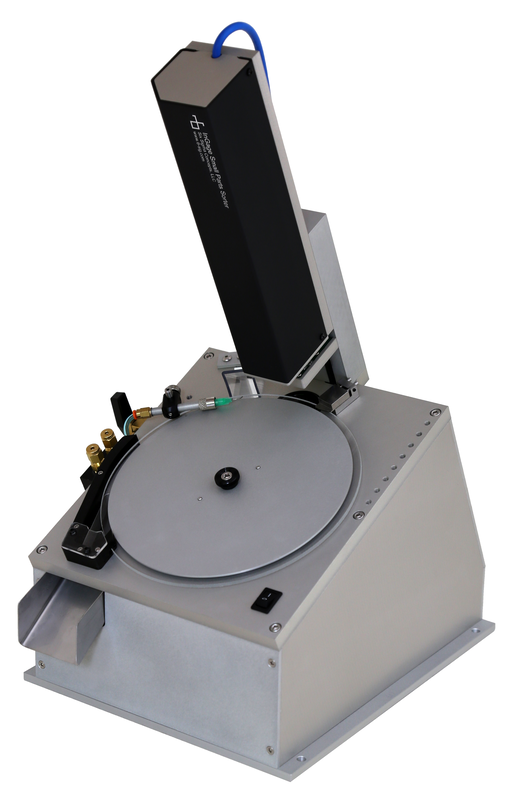

Orion Mini Small Parts Sorter

High Precision Compact Sorting Solution

Details:

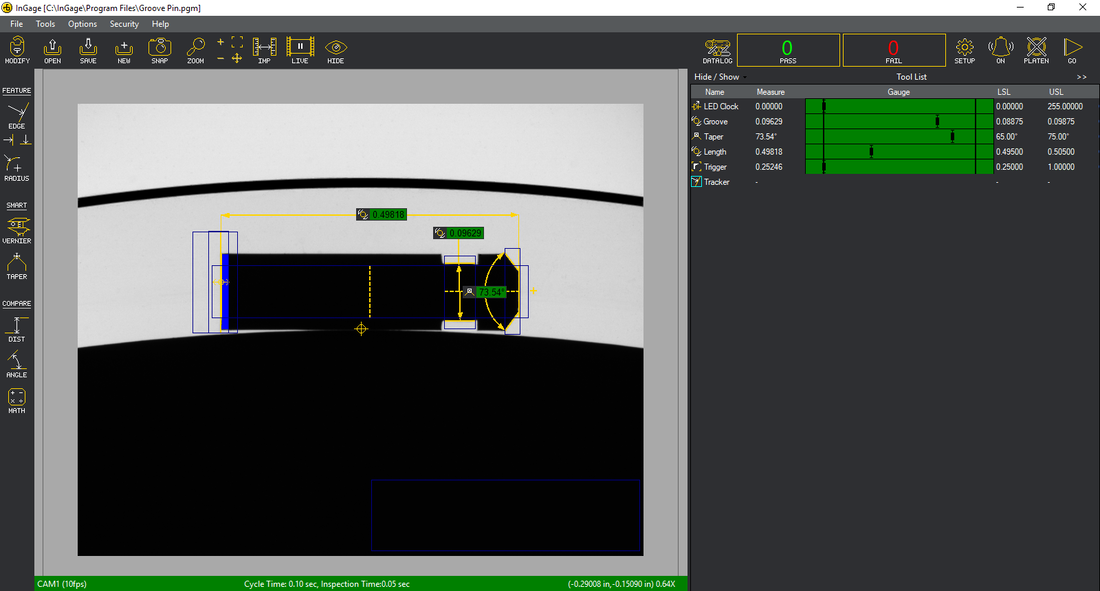

The Orion Mini uses a tilted counterclockwise rotating glass platen with a metal ridge for part transport. Fed parts first travel though the inspection window, where their presence triggers the system to take a backlit image of the part through the platen. This image is analyzed by Six Sigma Concepts' InGage™ software to extract features and dimensions. The part then travels to the pass ejector. If the part passed the software analysis, then the ejector will fire the part down a shoot. If the parts fails analysis, then the ejector will not fire and the part will continue past, falling into the fail shoot.

A relatively small inspection field of view, 17mm x 11mm, allows for high precision measurements of small parts. Both narrow cylindrical parts, such as pins and screws, and broad cylindrical parts, such as washers and gaskets, are able to be measured. Narrow parts lie sidewise on the platen, allowing for length measurements, while broad parts are viewed top down and will not be able to have their length measured. |

The Orion Mini is a turnkey optical inspection and sorting machine with rapid part measurement and defect detection. Image acquisition and analysis takes less than 100ms per part.

|

Sorting Specs:

|

Available Field of Views:

|

These are nominal specifications. For details about how your part will preform, please contact us.

Integration:

|

|

The Orion Mini uses InGage™ software for inspection and sorting. InGage™ software provides easy software tools to set inspection parameters. It also allows for adjustment of sorting speeds and timings. All inspection and sorting settings can be saved and recalled helping to minimize time to swap between parts. The Orion Mini's small 10" x 13" footprint allows it to be setup nearly anywhere with minimal hassle. A couple thumb screws control the only adjustments on the Orion Mini that require repositioning when switching between parts. An array of #10-32 taps allows for easy feed attachment.

|