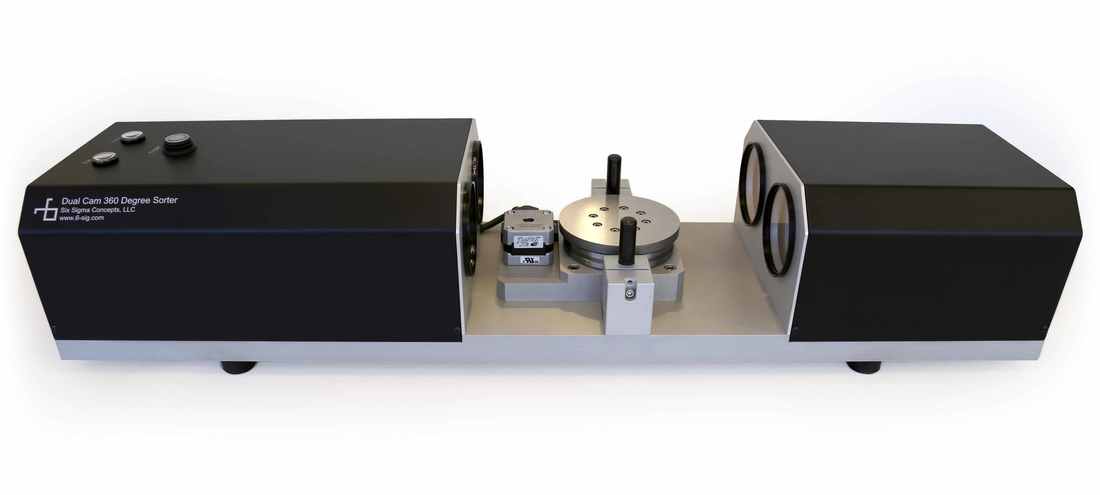

Gemini Dual Cam 360°

Precision Inspection of Large Diameter Parts

|

The Gemini: Dual Cam 360 provides a complete series of exterior profile measurements of large turned parts. Each measurement achieves extremely high accuracy and precision. This vision inspection system provides much higher accuracy over a larger area than traditional measurement methods, allowing for very precise measurements of both large and fine features with a single process.

|

System Specs:

|

For Turned Parts That:

|

These are nominal specifications. For details about how your part will preform, please contact us.

Details:

|

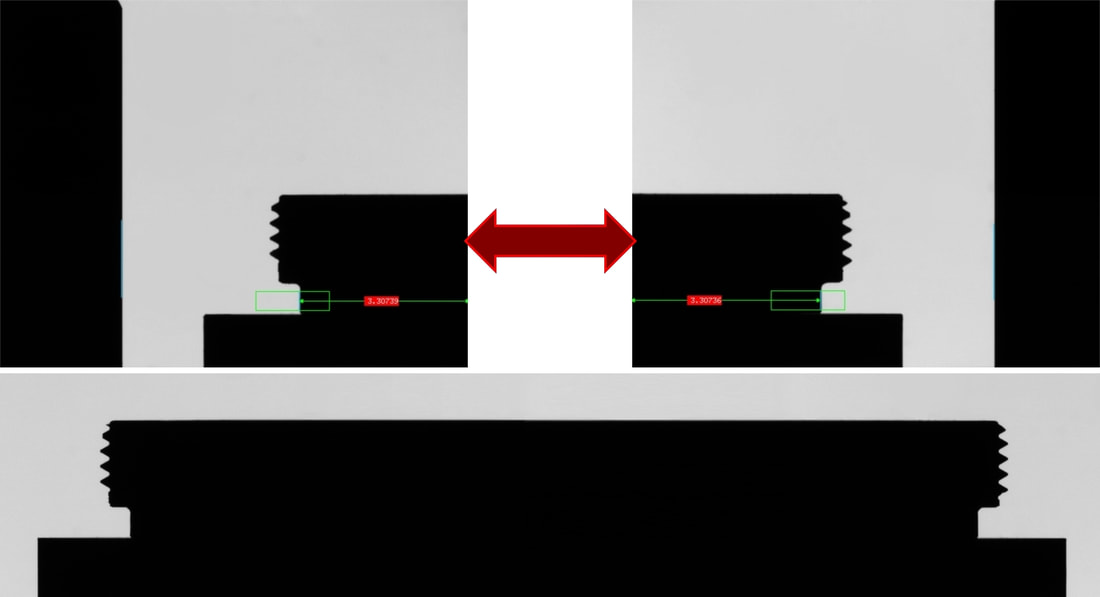

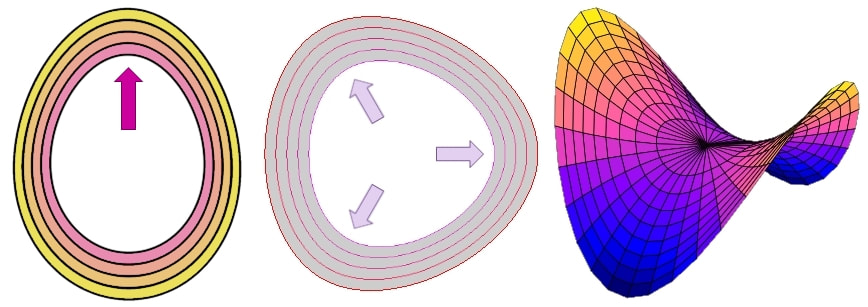

The Gemini is able to provide such high detail over a large area by stitching together multiple visual inspections. A series of reference points are used to calibrate the multiple images with each other. This combines high precision of small features, that can be achieved with a small field of view inspection system, with the ability to provide equally precise measurements over long distances. For example, with two cameras, one can look at either end of a large diameter threaded part and get a highly accurate measure of both the threads and the overall part diameter. Combining this with a rotation stage, allows for the complete profile of the part to be measured including deformation, such as out of round (OOR), multi-lobe (from a #-jaw chuck), and hyperbolic paraboloid (saddle shape) distortions.

|

Integration:

|

The Gemini system is a turn key operated inspection system. The principal of stitched inspection provides us wide latitude to be able to design systems that can inspect vastly different part dimensions. If desired, there are a number of sorting options available, depending on the part being inspected and its position in the manufacturing process.

|

|