Eclipse Track Sorter

Rapid Inspection & Sorting

Sorting Specs:

|

For Parts That:

|

|

|

These are nominal specifications. For details about how your part will preform, please contact us.

Details:

|

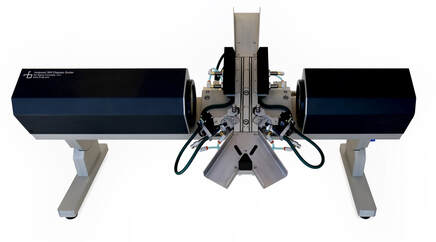

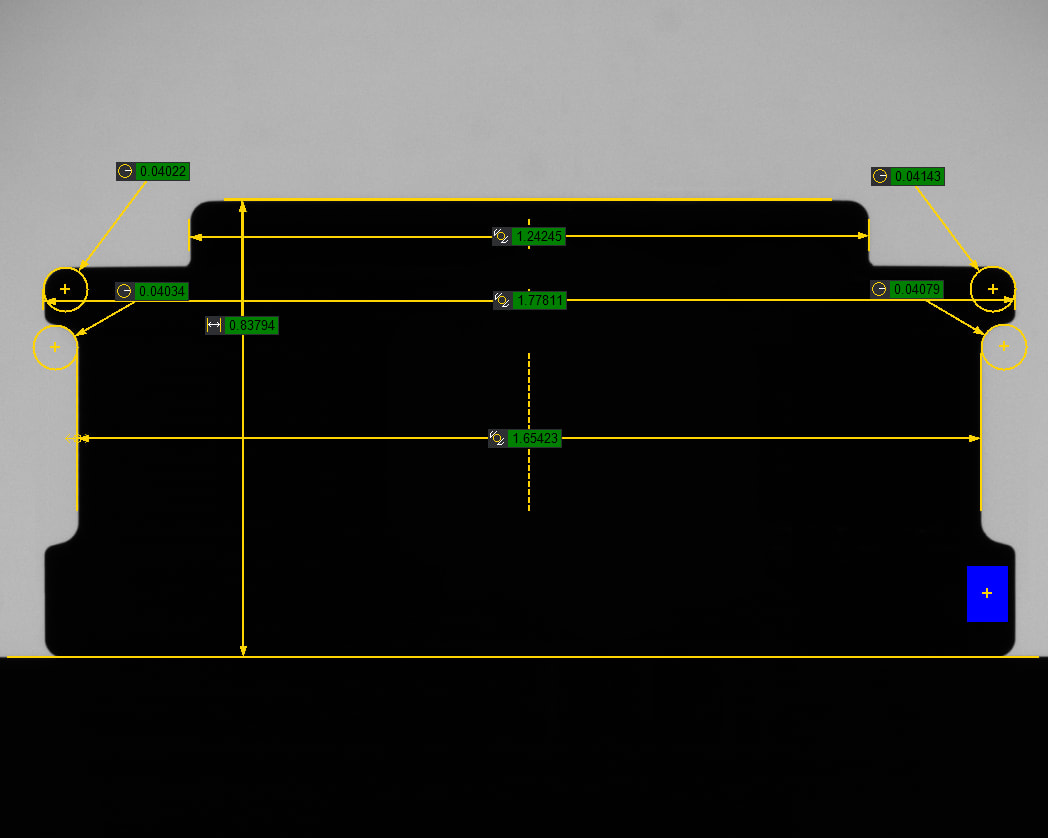

The Eclipse is a turnkey solution for the inspection of exterior part features. Parts are inspected on the fly; a snapshot is taken as each part slides down a pair of rails. Inspection is able to detect chips, burrs, and missing features. It is also able to measure feature heights, rounds, angles, diameters, and measure thread quality and properties. Due to the fly by inspection, the system is able to have a throughput of roughly 2 parts per second. This method only samples a single profile, to inspect the entire outer part profile, please see the 360° Variant below. The ID Variant of this platform adds the capability to inspect part ID to this system.

|

Integration:

|

The Eclipse is a ready to go, turnkey, easy to operate, inspection and sorting device. Our proprietary InGage™ software allows for easy measurement setup and fine control over sorting parameters. Additionally, InGage™ can inspect non symmetric parts of either orientation in the same process. IO available for part counts and other are information.

|

Eclipse: ID Variant

Additional Diameter Inspection

|

The ID Variant to the Eclipse adds a top down camera to the system. This additional camera allows for the inspection of the part's ID as well as the circularity of the part's ID and OD profiles. The additional camera does not affect the systems throughput rate. This will provide 100% inspection for parts such as tube cutoffs.

Additional Specs:

For Parts That:

|

Integration:

|

The ID Variant of the Eclipse effectively operates in the same way that the base unit does. InGage™ software allows for easy switching between either camera view. Inspection parameters are easy to add to or edit from either the top down or side on views. InGage™ is designed to be able to remove the interference of the rails, that are used for part transit, from affecting part inspection results. The ID Variant can be paired with the 360° Variant for a more complete part inspection.

|

|

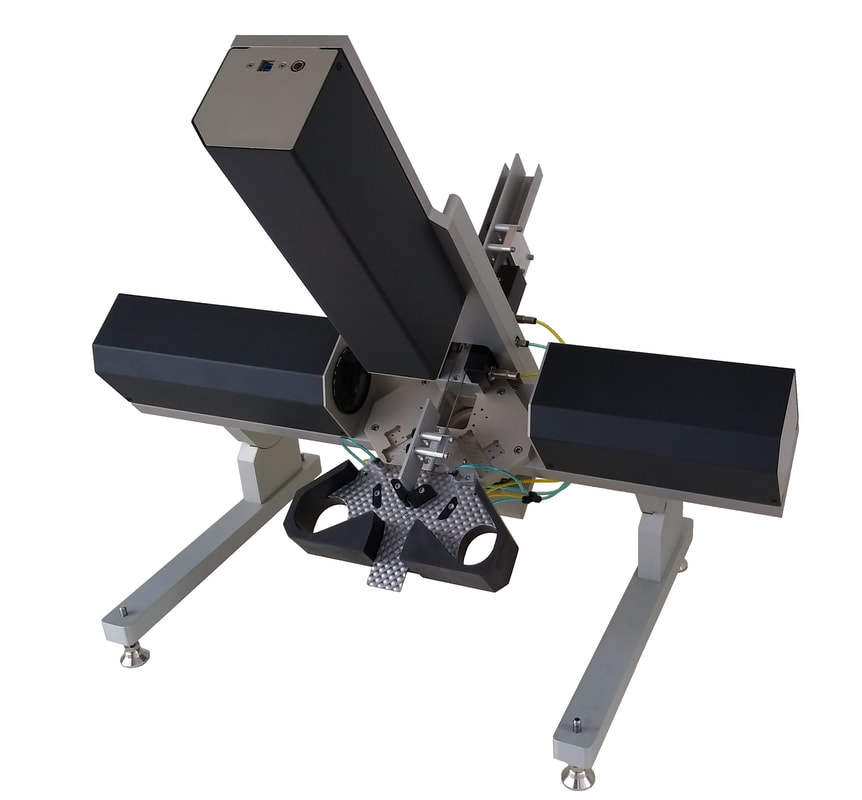

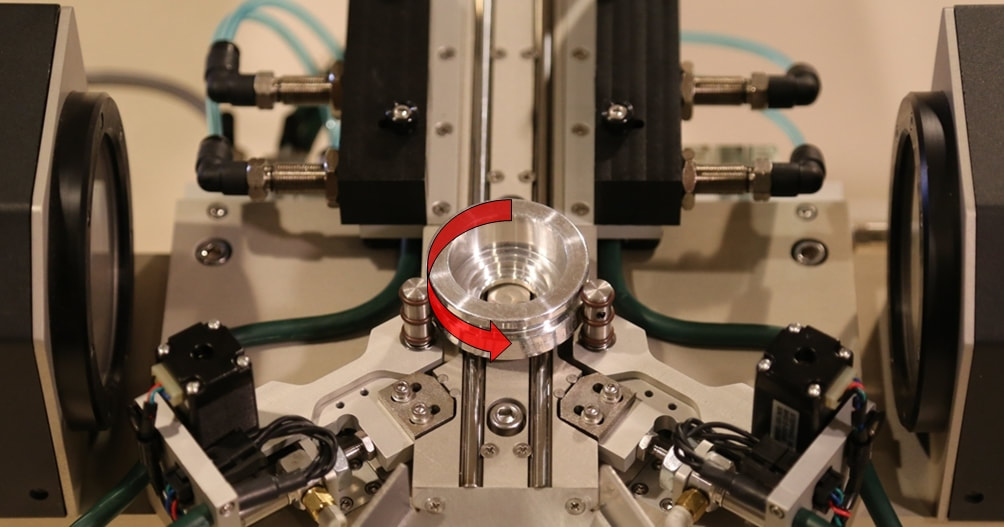

Eclipse: Indexed 360° Variant

Full Profile Inspection and Sorting

|

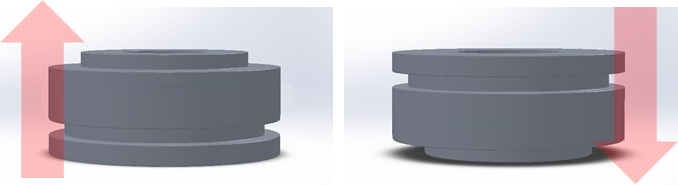

The Indexed 360° Variant of the Eclipse guarantees the detection of a number of elements not easily detectable in traditional profile visual inspection. This variant adds a stop that rotates each part to take a series of measurements. This process inspects the entire exterior part profile, including undercuts, for obstructions such as chips and burrs. Rotating the parts also allows for the measurement of part/feature distortion.

|

Additional Specs:

|

For Parts That:

|

|

|

Details:

The Indexed 360° Variant adds actuated rollers at the point of inspection, providing 100% inspection of the exterior features of turned parts. Each profile measurement of the part maintains an accuracy within 0.0001". Stopping and rotating each part reduces the sort rate to approximately 1200 parts per hour. This allows a single device to guarantee that the entirety of a product ships without any defects within the specified parameters. This variant inspects the entire profile of external features such as threads, undercuts, and chamfers. Also this variant guarantees that all external spot chips, wraparound chips, burrs, and missing features are detected. It is also able to measure feature heights, rounds, diameters, and measure thread quality and properties. Due to the fact that the part is continually measured as it rotates, the system is able to measure part distortion, such as out of round (OOR). Many distortion measurements can only be reliably found with visual inspection systems that take profile measurements while rotating the part. The Indexed 360° Variant can be paired with the ID Variant for a more complete part inspection.