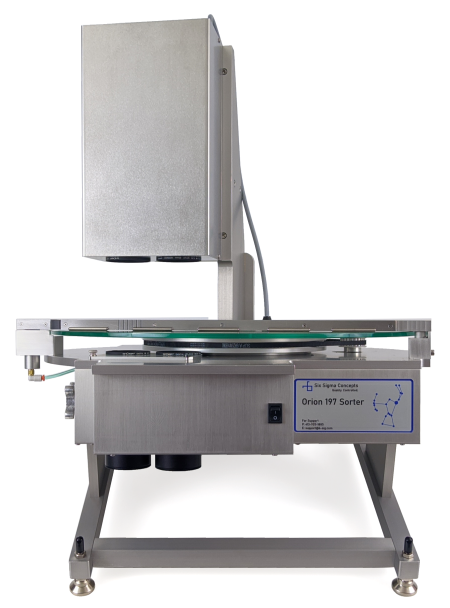

Orion197 Tilted Platen Sorter

Automated 360° Inspection & Sorting of Long Turned Parts

|

Six Sigma Concepts has partnered with Resec Systems to produce the Orion197, a new variant of Resec’s J197 tilted platen sorter. This variant offsets the camera's position along the rail. The part rotates as it is pushed along by the glass platen at the inspection point.

The Orion197 analyzes multiple real time profile images of each part as it transits and rotates through the inspection field. These additional images allow for consistent GD&T measurements of straightness, runout, and concentricity. Newly developed InGage software tools can inspect and measure to non-uniform features, such as flats, corners, thru holes and slots. 360° part inspection ensures that missing features, burrs, and chips are always detected. Sorting Specs:

For Parts That:

|

Integration:The Orion197 is designed to accommodate as large a variety of part sizes and shapes that can fit within and outside of its inspection window. Options are available to add variable tilt to the inspection angle and optical gate inspection triggering. The tilt option allows the system to be set such that parts that lie askew, such as a screw with a head, can be inspected at the proper profile angle. The optical gate inspection triggering option allows for inspections along parts longer than the inspection field of view.

|