InGage Inspection & Sorting Software

Powerful and Accurate Inspection Capability

Operation

|

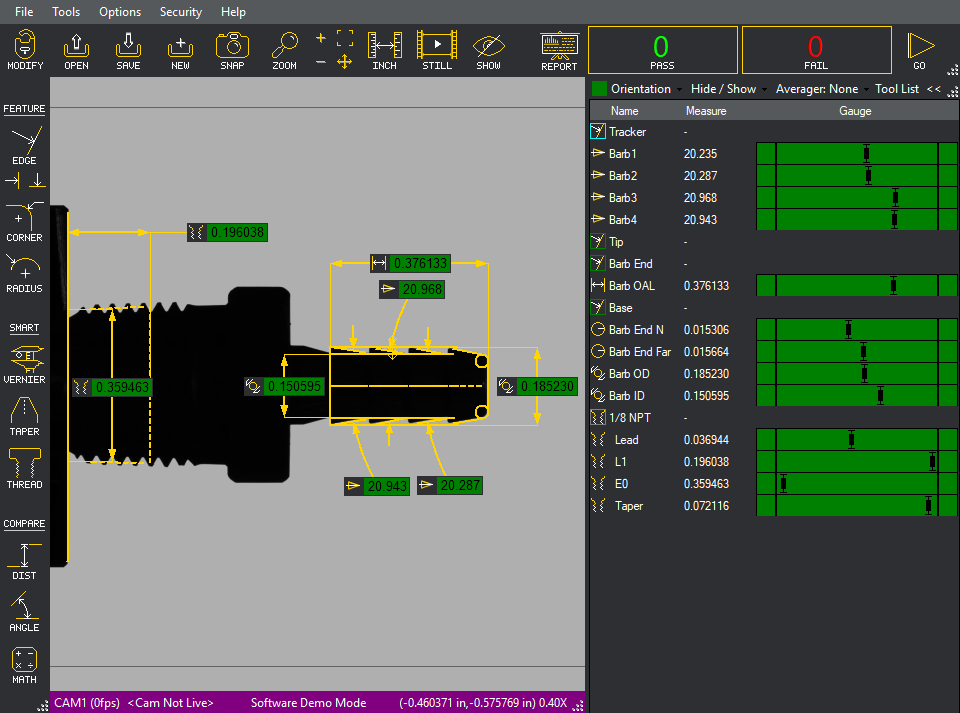

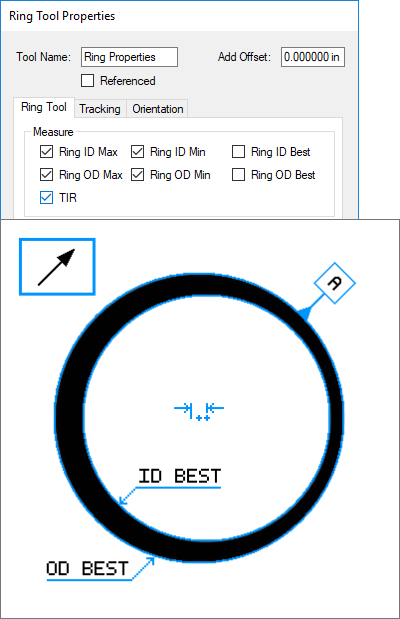

InGage's primary function is to perform metrology on images of backlit part profiles. This is accomplished by the operator selecting regions of the image to analyze with software tools. Different tools are designed to extract different features from within their designated window. Sets of tools, their regions, and additional settings are all saved as a part program. Switching between saved part programs lets the operator change between parts while maintaining identical measurement criteria.

InGage is able to operate in a number of configurations. Including multiple camera inputs, sorting system control, multiple part orientations, and much more. In addition to live inspection feedback, inspection results are automatically saved and can be published as a report. InGage allows the operator to select what information is saved and how that information is formatted and reported. Operating InGage is designed to be as intuitive as possible. Resources are available within InGage to help explain how features operate, such as button and property tool tips, operation directions, and a comprehensive manual. Additionally, video demos of the software are available online. Once operation proficiency is reached, complex inspection tasks only take a few minutes to setup. After the inspection program is setup, clicking a single button or pressing a single key will operate the execute the inspection program and any associated sorting. Typically inspection programs complete analysis and data recording within 100ms. |

Capabilities

|

|