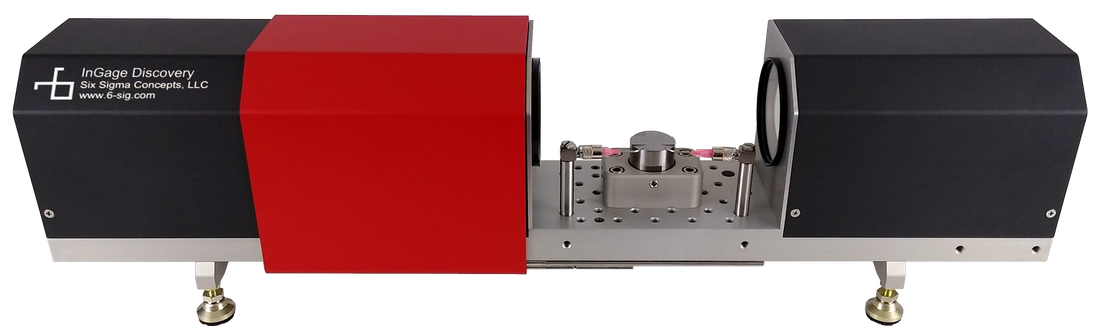

InGage Discovery

Quality Control Inspection & Sorting System

Save Time. Save Money. Save Face.

|

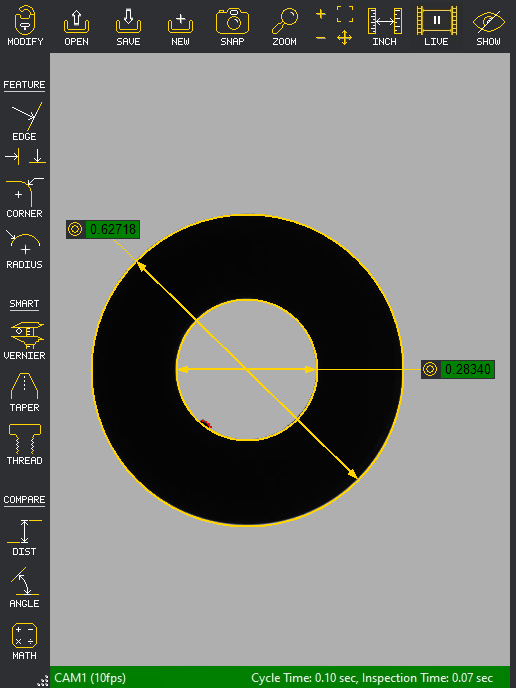

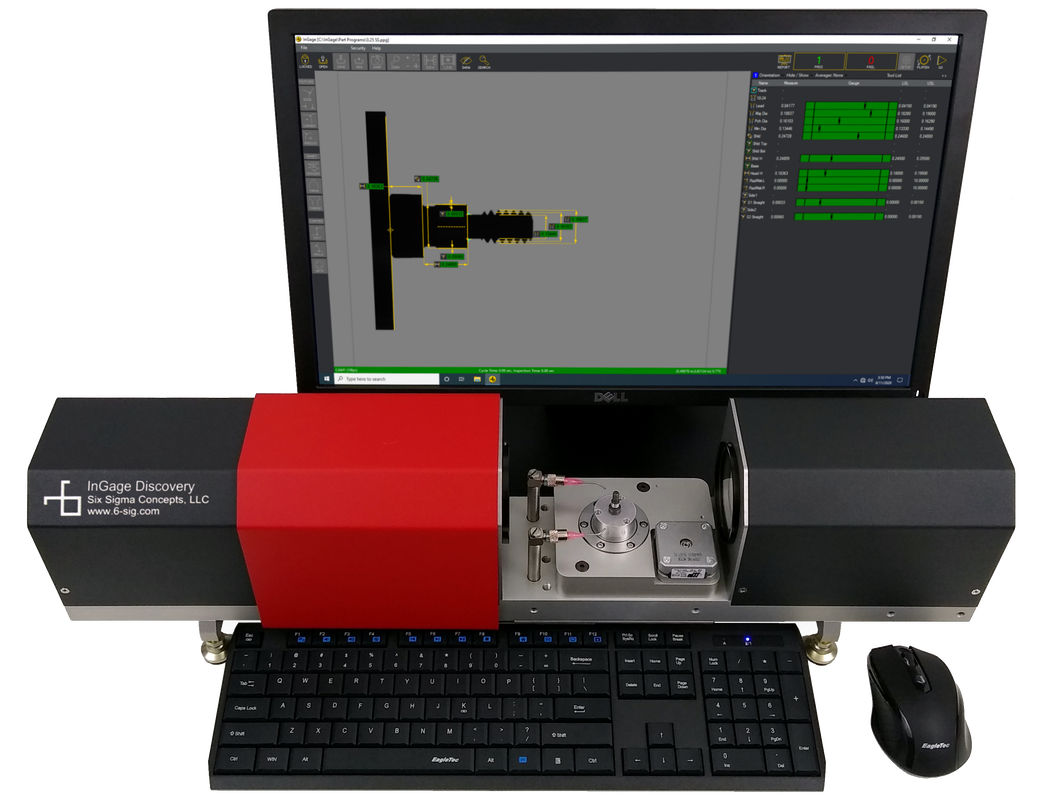

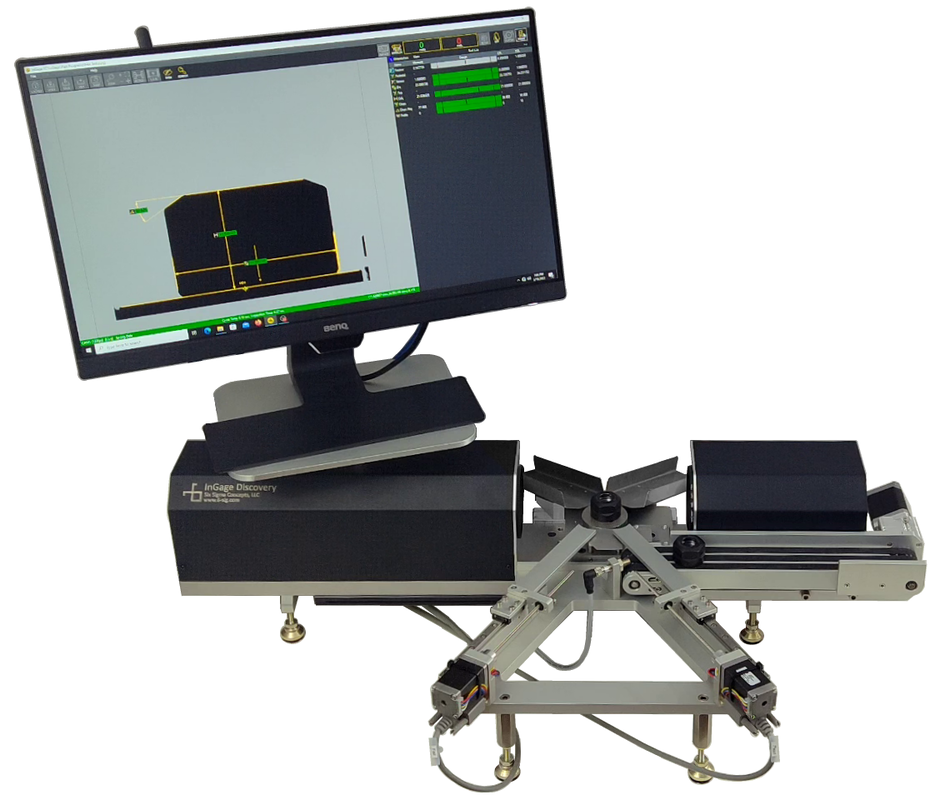

The InGage Discovery is a video measurement system capable of providing a rapid return on investment. On-screen measurements and recorded data update ten (10) times per second; making the complete part profile inspection and sorting process nearly instantaneous.

Each measurement is able to achieve extremely accurate results due to a combination of precise optical calibration and robust software tools. These precision measurements allow for the Discovery to supplant other time consuming and costly quality control equipment. Easy to Operate

The InGage Discovery is delivered ready to go. Users do not have to adjust any alignment, lighting, or focus to take accurate measurements. All of these conditions are optimized before the unit is shipped.

The Discovery is able to reproduce highly repeatable measurements independent of the operator. Once inspection and sorting criteria have been defined, measurements and sorting occur simply by placing samples in view of the camera. Inspection and sorting criteria are saved as part programs for future recall. Setting up a part inspection program takes just minutes. A large library of tips, descriptions, and instructions to aid with programing are integrated into the software. |

Features:

|

Available Field of Views:

Standard

|

For details on how the InGage Discovery will perform with your parts, please contact us.

Pin I/O

|

Description

|